LED panel light is a high-end indoor lighting fixture. Its outer frame is made of aluminum alloy through anodic oxidation. The light source is LED. The feeling of beauty.

The LED panel light has a unique design. The light passes through the light guide plate with high light transmittance to form a uniform plane luminous effect. The illumination uniformity is good, the light is soft, comfortable and bright, which can effectively relieve eye fatigue. LED panel lights can also prevent radiation and will not irritate the skin of pregnant women, the elderly, and children.

constitute

- Frame and bottom plate

The frame and bottom plate of the LED panel light have different heat dissipation properties according to different materials.

- Light guide plate and diffuser plate

The quality of the LED panel light guide plate is one of the most important factors that determine the quality of the LED panel light. Using a high-quality light guide plate can make the finished LED panel light emit more uniform light. There will be no dark spots, water ripples, etc.

- LED and patch

Good lamp beads not only have stable performance, good brightness, low light decay, but also have a much better color rendering index.

Basically, they are made with 11×23 or 11x26mil chips.

- Aluminum substrate

There are 4 aluminum substrates for the light input from four sides of the LED panel light, and 2 aluminum substrates for the light input from both sides.

- Power supply

Power supply is also the most important factor affecting the price of LED panel lights. Poor power supply directly affects the life of the LED panel light. The performance of UL power supply is relatively stable. There is also CE power supply.

- Packaging

Simply pack the four corners with a carton with a heaven and earth cover, and an outer carton for outer shell packaging.

- Accessories

The auxiliary materials include foam padding, tape, wire, and terminals, and the cost is about 5 yuan.

The main parameters

Light source type: SMD

Lighting mode: front light or side light

Dimensions and specifications: 1200×300mm 300×300mm 300×600mm

600×600mm 600×1200mm

Power: 9W 12W 18W 21W 22W 24W 36W 48W 72W 85W 90W

Input voltage: AC85-265V/50-60Hz

Material: aluminum alloy + (optical grade) acrylic

Protection class: IP40

Lifespan: >50000H

Color rendering: Ra>75

The service life of lamp beads is 50,000 hours

From the perspective of green lighting design, LED panel lights are environmentally friendly materials, low power consumption, luminous efficiency, lighting brightness, etc. It is gradually replacing the grid lights with T8 fluorescent lamps as the light source. The service life of LED panel lights is 10 times that of fluorescent lamps.

Installation form

- Can be inlaid on the ceiling, wall and installation surface;

- It can be hung on the ceiling or under the installation body. When inlaid on a white ceiling, the entire ceiling is in one color, very beautiful, neat and coordinated;

- LED panel light adopts broadband voltage design (AC85-240V/50-60Hz), which can be used in all countries in the world; high-power LED adopts isolated power supply, constant current or constant voltage drive, high power efficiency, no pollution to the power grid, and stable performance ,Safe and reliable;

- LED panel light is a new type of surface light source that adopts the backlight technology of LCD TV. It has soft light and beautiful appearance. and suppliers;

- LED panel light seems to be just a simple lighting fixture, but due to its high market positioning, customers have extremely strict requirements on the quality of this product, and the product itself involves materials, thermals, optics, structure, hardware , electronics and other fields, the general company does not have a complete development team, sufficient development experience and follow-up supply chain management capabilities, it is difficult to develop successfully, and the understanding of market requirements is not clear, so a lot of development costs are invested in exchange for What’s more is just a product that customers don’t approve of.

model

Flat lay LED panel light

LED panel downlight

LED panel downlight(8 photos)

Recessed LED Panel Light

Ceiling LED Panel Light

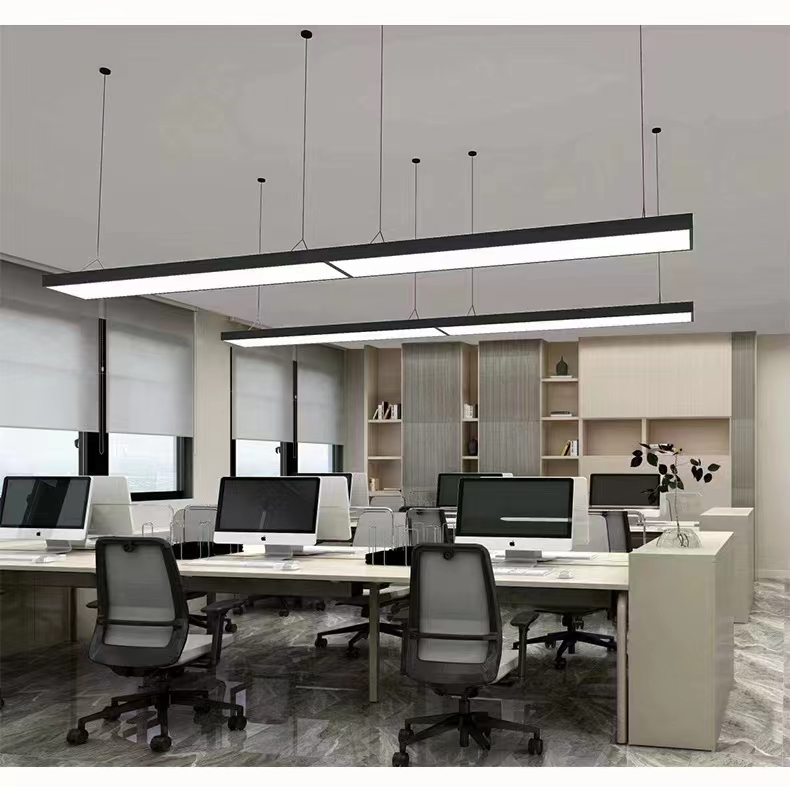

Hanging LED Panel Light

Round LED Panel Downlight

Round Ceiling LED Panel Downlight

Application range

LED panel lights are widely used, and there is a tendency to replace grille lights; LED panel lights are mainly used in:

600*600mm LED panel light

600*600mm LED panel light

- Ceiling (replacing the original grid light);

- Walls (not only for lighting purposes, but also for artistic expression);

- Installation body (pursuing the combination of practicality and art, convenient and simple installation);

- Others (can also be used in other places, such as train carriages or large mobile cars, counters, etc.);

color temperature

True white 5500-6500K

Natural white 4000-4500K

Warm White 2800-3500

Advantage

LED panel lights use ultra-high-brightness LEDs as light sources, suitable for indoor lighting in hotels, bars, western restaurants, coffee shops, home interior decoration, etc., and can directly replace the original ordinary fluorescent lamps, and their brightness is higher.

The main performance and characteristics of LED panel lights are as follows:

- Flexible LED panel light design

LED is a point-shaped illuminant. Through the flexible combination of points, lines and surfaces, designers can design light sources of various shapes and particles according to customer requirements. The design is very flexible.

- LED panel lights have high illumination

The LED panel light adopts a uniformly luminous reflective panel and a sealed design, combined with a high-efficiency light guide plate and made of aluminum alloy materials. The luminous effect is uniform and the illumination is higher.

- LED panel lights generate less heat

The LED panel light has a thin and light appearance, complete heat dissipation function, low power and less heat generation.

- Long service life of LED panel lights

LED theoretical life of up to 100,000 hours. If calculated by 8 hours a day, its theoretical life span is more than 27 years. The theoretical life of the CPL lamp cup even exceeds 100,000 hours.

- LED panel lights can be changed in various ways

LED panel light can adjust the light color according to different needs and environmental changes, not only does not produce radiation and glare, but also protects eyesight, and the light color is milder.

- LED panel lights have strong vibration resistance

In LED panel lights, the LED light source is a high-hardness resin illuminant rather than tungsten glass, which is not easy to damage, so its vibration resistance is relatively high, and the ambient temperature adaptability is strong.

- Strong control ability of LED panel lights

The LED panel light can be controlled by various dynamic programs through an external controller, and can adjust the color temperature and the degree of brightness and darkness.

- Low power consumption of LED panel lights

At the same time, LED panel light lighting technology is also a green lighting technology. The products do not contain mercury, have less waste, and there is almost no pollution in the manufacturing process; semiconductor lighting is recyclable and recyclable, which is of great importance to the sustainable development of the economy and society. effect.

Part Edit Broadcast

- Aluminum frame of panel light:

It is the main channel for LED heat dissipation. The appearance is simple and elegant. ZY0907 can be used. The cost of mold stamping and mold opening is low, and the processing cost is also low; the IP level of the die-cast aluminum frame can be higher, the surface texture is good, and the overall appearance is beautiful, but the mold cost is invested in the early stage higher.

- LED light source:

Usually led lamp beads use 3528, and some people use 3014 and 5050. The cost of 3014 and 5050 is low, and the light effect is slightly worse. The key is that the design of the light guide network is difficult. 3528 has high light efficiency and good versatility.

- LED light guide plate:

The side LED light is refracted through the dots to make the light evenly exported from the front. The light guide plate is the key point of the quality control of the LED panel light. If the screen design is not good, the overall light effect will be very poor. Generally, the center will be bright and the sides will be dark, or there will be bright light bands at the light entrance, or local dark areas will be visible, or there will be inconsistent brightness at different angles. To improve the light efficiency of the light guide plate mainly depends on the design of the dots, followed by the quality of the plate, but there is no need to be superstitious about the plate of the first-line brand, the light transmittance of qualified plates is usually almost the same. Generally, small LED lamp factories directly buy public light guide plates for use, so there is no need to re-prototype the design, and the public plates used by many manufacturers are usually of qualified quality.

- LED diffusion plate:

The light from the light guide plate is evenly exported, and it can also play a role in blurring dots. The diffuser plate generally uses acrylic 2.0 plate or PC material, almost PS material, the cost of acrylic is lower and the light transmittance is slightly higher than PC, acrylic is brittle and anti-aging performance is weak, the price of PC is slightly expensive, but the anti-aging performance powerful. The dots cannot be seen after the diffuser plate is installed, and the light transmittance should be around 90%. The light transmittance of acrylic is 92%, that of PC is 88%, and that of PS is about 80%. You can choose the material of the diffuser plate according to your needs. Most manufacturers use acrylic material.

- Reflective paper:

Reflect the residual light on the back of the light guide plate to improve light efficiency, generally RW250.

- Rear cover:

The main function is to seal the LED panel light, generally use 1060 aluminum, and it can also play a role in heat dissipation.

- Driving power supply:

There are two kinds of led drive power supply, one is to use constant current power supply, this mode has high efficiency, PF value is as high as 0.95, and the price is high; the other is to use constant voltage and constant current power supply, which has stable performance, but low efficiency and high cost. Generally, this mode is used This kind of power supply is mainly exported, and the other party requires certification requirements, and a power supply with safety regulations must be used. In fact, it is very safe to use a constant current power supply at home, because it is difficult for users to access the power supply, and the lamp body itself uses a safe low-voltage power supply.

- Install the pendant:

Suspension steel wires, mounting brackets, etc. are used to install and fix accessories.

From the perspective of quality control, it is most effective to spend additional money on LED light sources and LED light guide plates to improve light efficiency. From the perspective of marketing, it is most effective to spend additional money on aluminum frame cover plate pendants, etc. Product grade can be improved.