FAQ

FAQ

How to deal with FAQ led and lighting faq in a timely manner?

According to relevant lamp faq questions and product categories, please refer to the relevant corresponding document pages; you can also provide general online customer service and email feedback related technical support…

LEDs Storage and Soldering Operation

1. This specification stipulates the proper storage and correct use of LED light-emitting diodes. Avoid damage to the original characteristics of LED lamp beads due to improper operation during storage and use, which will have a negative impact on its production.

2. Scope

This specification applies to Queendom Technology Co., Ltd. for LED storage and soldering operations.

3. Storage

1. In order to prevent moisture, LEDs should be stored in a dry and ventilated environment, the storage temperature is -40°C- +100°C, and the relative humidity is below 85%.

2. It is better to use the LED within 3 months in its original packaging to avoid rusting of the bracket. 3. After the packaging bag of the LED is opened, it should be used up as soon as possible. At this time, the storage temperature is 5°C-30°C, and the relative humidity is below 60%.

4. Use

1. Before use, the dehumidification and dehumidification process must be done according to the LED instructions to prevent a large number of dead lights and other defects caused by moisture during use.

2. Do not use unknown chemical liquid to clean the LED, because it may damage the surface of the LED resin, or even cause colloidal cracks. If necessary, please immerse the LED in alcohol at room temperature for cleaning within one minute.

5. Forming

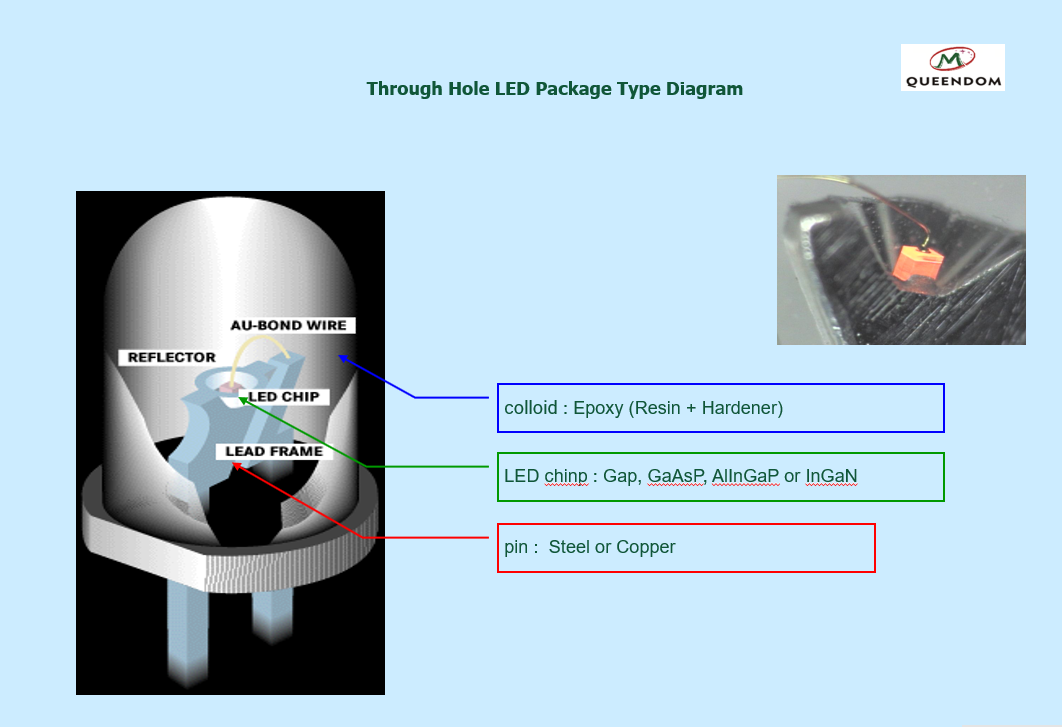

1. Do not form during or after welding. If necessary, forming must be done before welding. 2. Any act of squeezing the resin may damage the gold wire inside the LED.

6. Welding

1. During the soldering process, do not apply any external pressure to the lamp body, otherwise cracks may appear inside the LED, which will affect its internal gold wire connection and cause quality problems.

2. The colloid must not be immersed in the solder.

3. When soldering, there must be at least 2 mm gap between the soldering point and the lower edge of the colloid. After the soldering is completed, it is necessary to take three minutes to let the LED return from the high temperature state to the normal temperature.

4. If soldering linearly arranged LEDs on the same PCB with a soldering iron, do not solder two pins of the same LED at the same time.

5. When soldering with a soldering iron, it is required to use a soldering iron below 30W. There are two ways of LED welding, the specific parameters are as follows:

Soldering iron temperature: 295°C±5°C Soldering time: within 3 seconds (only once) Wave soldering temperature: 245°C±5°C Soldering time: within 3 seconds

Note: Improper control of soldering temperature or time may cause deformation of the LED lens or open circuit inside the wick resulting in dead light.

Seven, static electricity protection Static electricity can cause LED function failure, it is recommended to prevent static electricity from damaging LED.

1. Operators must wear anti-static wristbands and anti-static gloves when testing and assembling LEDs.

2. Welding equipment and testing equipment, work tables, storage racks, etc. must be well grounded.

3. Use an ion fan to eliminate static electricity generated by friction during storage and assembly of LEDs.

4. The material box for LED is anti-static material box, and the packaging bag is electrostatic bag.

8. Suggested method of use

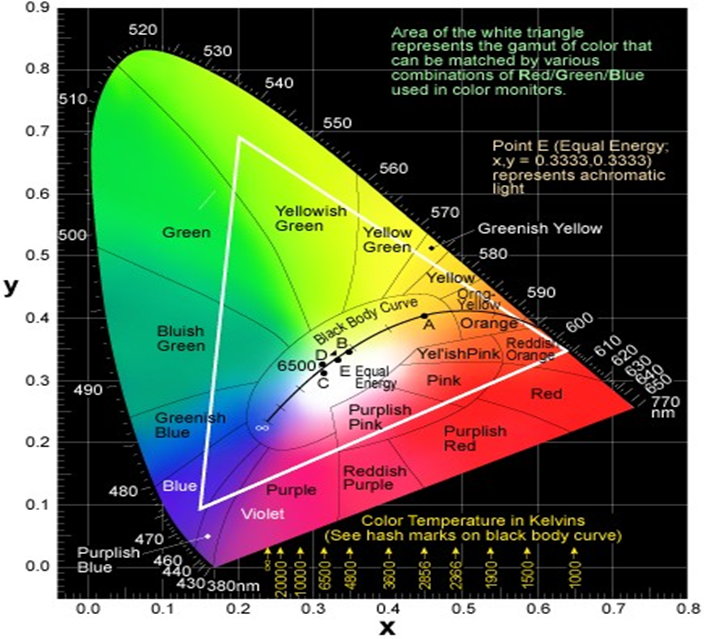

In order to obtain uniform brightness and color, the same current should be used for the same batch of LEDs, and multiple packages should not be mixed to avoid brightness differences.

LED tube installation method

The T8 LED tube is equipped with a constant current source, no ballast or starter required. Generally speaking, for lamps above T8 LED tubes, since the space of the lamps is large enough, a constant current source can be installed in the lamps. Therefore, during the installation process, the ballast and starter in the original bracket can be disassembled without use, and the lamp tube can be directly installed.

T5 and T4 LED fluorescent lamps cannot be installed with a constant current source due to the small size of the LED tube, so the constant current source can only be installed on the bracket. Therefore, general manufacturers will configure brackets when making T4T5. The stand is equipped with a constant current source. Additionally, the tubes are oriented when installed. The direction is reversed and the light does not come on. We’re thinking of adding some switching circuitry so that it works even if the lamp is upside down.

Voltage: Although the T8 LED tube has wide voltage adaptability, it can work normally for AC 85V-AC 245V. However, if the voltage is too high or too low for a long time, it will affect the power factor of the constant current source, that is to say, it will have a slight impact on the energy saving effect. At the same time, it will also affect the life of the constant current source. Therefore, it is generally necessary to select a fluorescent tube with an appropriate voltage. For example, when the city power supply is 110V, we should use our specially designed 110V city power fluorescent tube.

Heat Dissipation: The LED light is equipped with an aluminum heat dissipation housing. Under normal circumstances, there is no problem with heat dissipation. However, if it is used in a place with heavy dust, it should be cleaned regularly to prevent dust from covering the radiator and affecting heat dissipation.

Waterproof: The LED fluorescent lamp consists of upper and lower parts: the upper part is an aluminum heat sink, and the lower part is a diffuser. There is a gap at the connection. Therefore, it is necessary to prevent oily smoke and water vapor from entering. If it is used in a place with dense smoke and water vapor, it is recommended to cover it. A normal cover will do.

Vibration: LED fluorescent lamps have a strong ability to resist vibration. As long as it is not a violent impact, it will generally not cause damage. But it may affect the diffuser to some extent. Traditional fluorescent lights are made of glass and have a near vacuum inside. Vibration may cause explosion. Pay special attention to vibrations.

Precaution

There are two situations for T8 LED lamp installation

When installing, remove the original fluorescent lamp and replace it with an LED fluorescent lamp, and remove the ballast and starter, so that 220V AC power can be directly added to both ends of the LED fluorescent lamp. (common in the European Union)

When installing, remove the original fluorescent lamp, replace it with an LED fluorescent lamp, remove the ballast and starter, so that the 220V AC mains can be directly connected to the same end of the LED fluorescent lamp. (American standard)

What are common LED failures?

What are common LED failures?

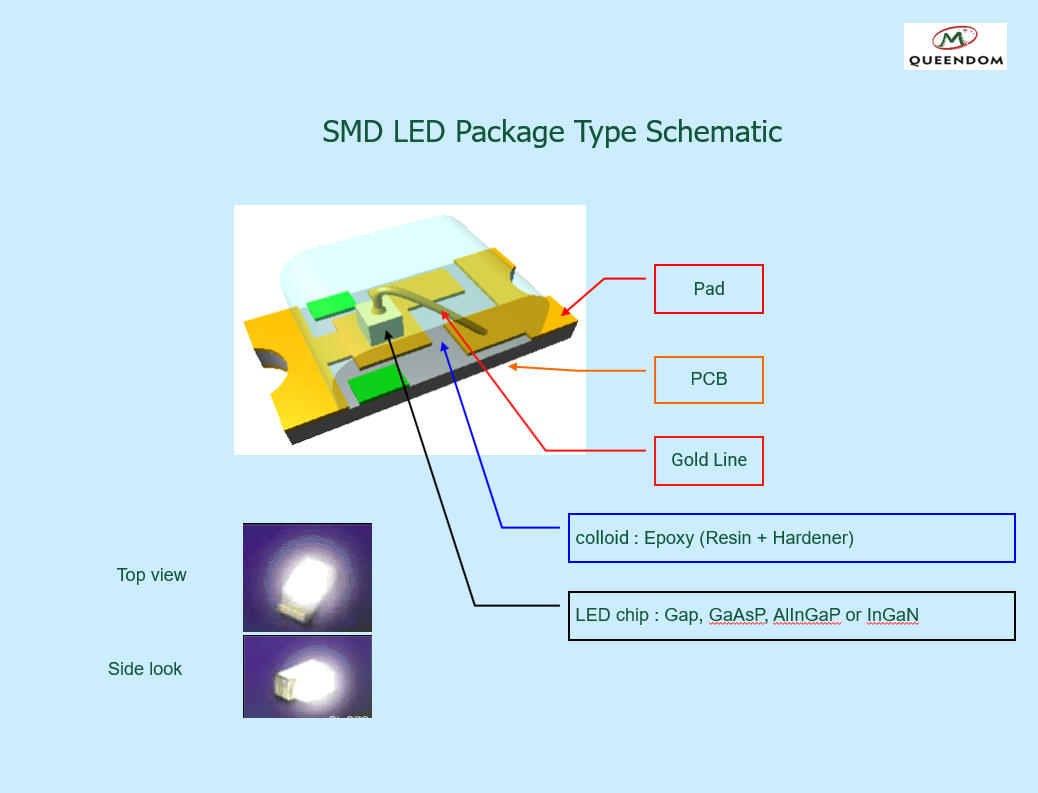

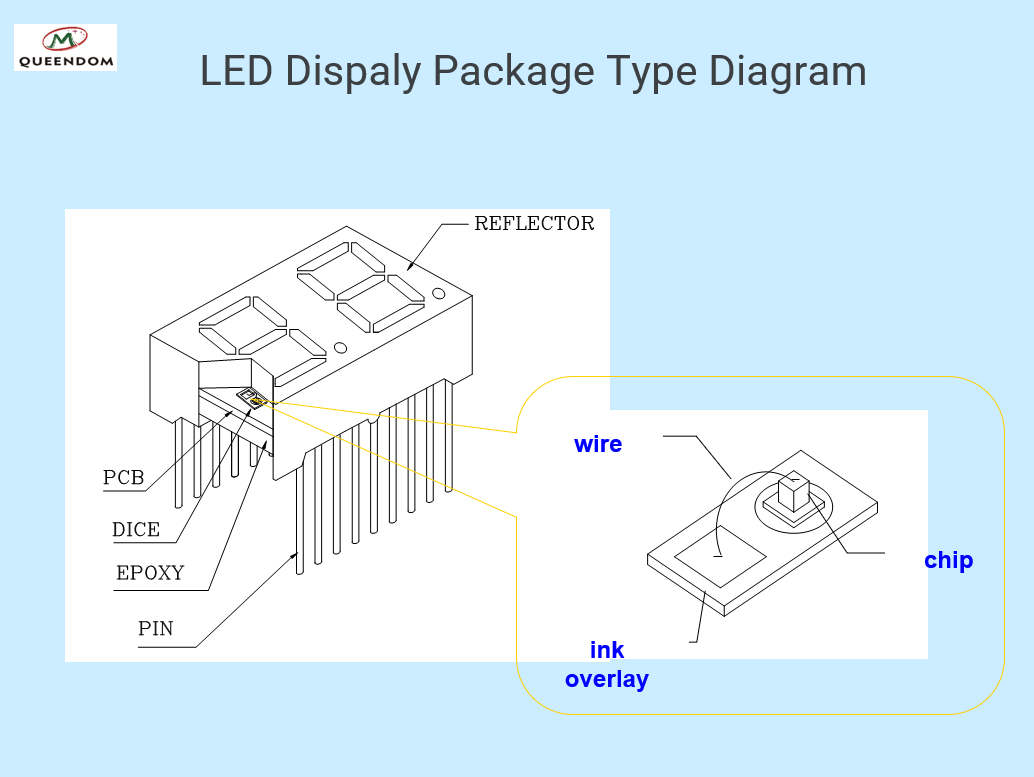

LED does not work after SMT or SMD assembly PCB, problem analysis Analysis of the problem of dead light after the lamp bead is pasted on the board

In the process of production, some LEDs will always encounter the phenomenon that one, one string, or several strings of lamp beads cannot be lit when testing after mounting the board. To make a summary for this phenomenon: The lamp is dead during the welding process.

1. Common welding methods can be divided into electric soldering iron welding, heating platform welding and reflow soldering, etc.

A. Soldering with electric soldering iron is common, such as sample making and maintenance. In order to save costs, most existing manufacturers buy back soldering irons that are mostly unqualified and low-quality products. Most of them are poorly grounded and have leakage. The welding process This is equivalent to forming a circuit between the tip of the soldering iron that is leaking electricity–the soldered LED–the human body–the earth, that is to say, it is equal to tens of times-hundreds of times the voltage that the lamp bead bears is added to the LED lamp bead, instantly Burn it out. Note: The situation of connecting the electrostatic belt will be more serious, because when the human body is connected with the electrostatic belt, the resistance of the loop to the ground is smaller, and the current passing through the human body to the lamp bead will be greater. This is what many people say that there is obviously static electricity The belt still has the problem of so many lamp beads being damaged.

B. Dead lamps caused by heating platform welding. Due to the continuous sample list of lamps, most enterprises meet the needs of small batches and sample lists. Due to the advantages of low equipment cost, simple structure and operation, etc., the heating platform has become the best production tool, but , due to the use environment (such as: the temperature cannot be kept constant in places with fans) and the control of the welding operator’s proficiency and welding speed, it has become a big problem causing dead lights. In addition, there is the heating platform. Equipment grounding.

C. Reflow soldering. Generally, this soldering method is a reliable production method and is suitable for mass production and processing. If it is not operated properly, it will cause more serious consequences of dead lights, such as unreasonable temperature adjustment and poor grounding of the machine.

2. Improper storage causes dead lights

This kind of problem is common, because the moisture-proof problem is not paid attention to after opening the package, because the sealing glue of the lamp bead is mostly made of silica gel material, which has certain water absorption characteristics, after the damp lamp bead is attached to the board, it goes through a high-temperature welding process Silicone will expand with heat and contract with cold, and the gold wire, chip, and bracket will be deformed, causing the gold wire to shift and break, and the lamp will not light up. Therefore, it is recommended that LEDs be stored in a dry and ventilated environment, and the storage temperature is -40 ℃- +100℃, relative humidity below 85%; it is better to use the LED within 3 months in its original packaging to avoid rusting of the bracket; when the LED packaging bag is opened, it should be used up as soon as possible. The storage temperature is 5°C-30°C, and the relative humidity is below 60%.

3. Chemical cleaning

Do not use unknown chemical liquid to clean the LED, because it may damage the surface of the LED colloid, or even cause colloidal cracks. If necessary, please clean it with an alcohol cotton swab in a room temperature and ventilated environment, and the time is controlled within one minute.

4. Deformation causes dead lights

Due to the deformation of some of the lamp boards, the operator will have to reshape the board. Due to the deformation of the board, the lamp beads on it will also be deformed at the same time, and the gold wire will be broken, causing the lamp to not light up. It is recommended to have this type of board in the Shaping before production. Longer ones may be deformed and broken during production, assembly and moving. In addition, it is caused by stacking. For the convenience and smoothness of the production process, the lamp panels are stacked randomly. Due to gravity, the lamp beads on the lower layer will be deformed by force and damage the gold wire.

5. The heat dissipation structure, power supply and lamp board do not match

Due to the unreasonable design or selection of the power supply, the power supply exceeds the maximum limit that the LED can withstand (overcurrent, instantaneous impact); the heat dissipation structure of the lamp is unreasonable, which will cause dead lights and premature light failure

6. Factory production line grounding

It is necessary to check whether the general ground wire of the factory is in good condition.

7. Static electricity

Static electricity can cause LED function failure, it is recommended to prevent ESD damage to LED.

A. Operators must wear anti-static wristbands and anti-static gloves during LED testing and assembly.

B. Welding equipment and testing equipment, work tables, storage racks, etc. must be well grounded.

C. Use an ion fan to eliminate the static electricity generated by friction during storage and assembly of LEDs.

D. The material box for LED is anti-static material box, and the packaging bag is electrostatic bag.

E. Don’t be lucky, touch the LED casually. The abnormal phenomena that will appear in the LED damaged by ESD are:

a) Reverse leakage, the light one will cause the brightness to decrease, and the serious one will not light up.

b) The forward voltage value becomes smaller. LED cannot emit light when driven by low current.

9. Poor welding causes the lamp to not light up.