ceramic packaging semiconductors

Ceramic high power led material

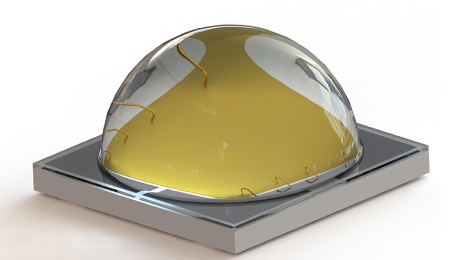

Ceramic high-power LEDs are composed of ceramic substrates, solid primers, chips, gold wires, fluorescent powder (white light), silica gel and other main materials.

1. The function of ceramic substrate:

Ceramic substrates are divided into alumina ceramic substrates and aluminum nitride ceramic substrates. The thermal conductivity of alumina ceramic substrate is 30W/M*K, generally used for 1-3W, aluminum nitride ceramic substrate is 100-200W/M*K, generally used for 5W.

Material of ceramic substrate:

Used for conduction, heat dissipation and connection. It is mainly to sinter ceramic powder into a ceramic substrate, and then distribute copper, nickel plating, copper plating, and silver plating on the substrate.

2. Solid primer: Different from low-power primer, ceramic high-power LED diodes use nano-silver glue and poured gold-tin alloy flux because of their high power and high heat. The crystal primer has the functions of fixing the chip and conducting electricity.

3. The role of the chip: The chip is the main component of the LED light source and is a luminous semiconductor material.

a) Chip composition: The chip is made of gallium phosphide (GaP), gallium aluminum arsenide (GaAlAs) or gallium arsenide (GaAs). Gallium nitride (GaN) and other materials, and its internal structure has unidirectional conductivity.

b) Chip structure: Weld single-wire positive polarity (P/N structure) wafers and double-wire wafers. Wafer size unit: mil. Wafer pads—typically gold or aluminum pads. The pad shape is round, square, cross and so on.

c) Luminous color: The luminous color of the chip depends on the wavelength. The classification of common visible light is roughly: far red light (700-7400nm), deep red light (640-660nm), red light (615-635nm), amber light (600nm) -610nm). Yellow light (580-595nm). Yellow-green light (565-575nm). Pure green light (500-540nm). Color (450-480nm). Purple (360-430nm).

4) High-power LED chip: It is divided into two processes: vertical structure and horizontal structure. The vertical structure chip needs gold wire.

4. Wire material

a) Gold wire: 99.99% gold wire, connect the chip PAD (welding pad) with the bracket, and make it conductive. Au: The elongation rate is 2-6%,

a) Gold wire size: 0.9mil.1.0mil.1.2mil.1.5mil etc.

5. Phosphor powder, mainly used to adjust the color of white light, monochromatic light does not need phosphor powder.

6. Mold top glue: mainly used to protect chips and gold wires.