With the continuous improvement of people’s quality of life in modern society, the demand for using waterproof lamps is also increasing. Waterproof lamp is a type of lamp that has undergone special treatment, can be waterproof and moisture-proof, and is suitable for use in humid and rainy environments. It is increasingly widely used in home life, commercial venues, and outdoor advertising display, and is loved and sought after by consumers. Below, we will elaborate on the characteristics and usage of waterproof lamps from multiple aspects. Characteristics of waterproof lamps One of the characteristics of waterproof lamps is their good waterproof performance. Due to the special treatment of the shell of the waterproof lamp, it can better resist the erosion of rainwater and moisture, thus working more stably. In humid indoor and outdoor environments, waterproof lights can still ensure good lighting effects, providing convenience for people’s lives and work. Secondly, the installation and use of waterproof lights are also relatively simple. The shell of the waterproof lamp is made of high-quality materials, which has advantages such as strong toughness, shockproof, and shatterproof. During the installation process on the wall or ceiling, the opening and closing of the rear cover and the replacement of the light bulb are also more convenient. Even in difficult working environments, waterproof lights can maintain a stable working state and serve people’s lighting needs. Long service life, energy-saving and energy-saving In addition, waterproof lights also have a longer lifespan and energy-saving characteristics. The brand new waterproof light has a long service life, which can save a lot of time and effort in cleaning and debugging during normal use. Moreover, waterproof lamps using LED light sources can achieve better energy conservation than traditional lamps. As mentioned above, waterproof lamps are a type of lamp used in humid and rainy environments, and are increasingly widely used in the industry due to their obvious advantages such as waterproofing, energy conservation, and long service life.

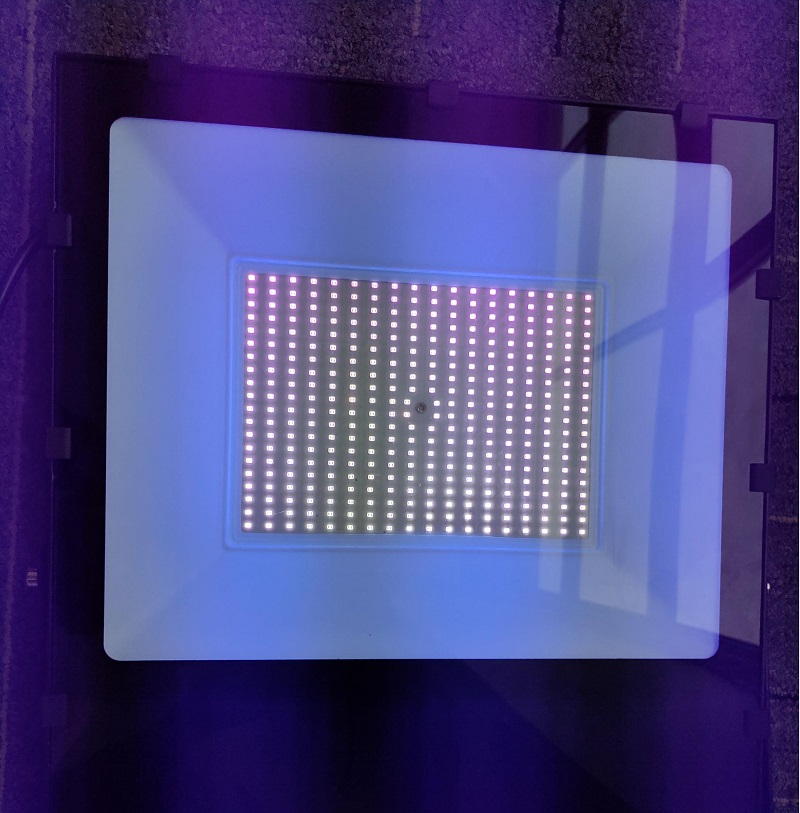

A Plant Grow Light is a type of lamp that provides essential supplementary light for plants to promote their growth and development, and has proven to be useful. Compared to ordinary lamps, Plant Grow Lightss have significant differences and advantages. Let’s explore in detail the purpose of Plant Grow Lightss and their differences from ordinary lamps. The difference between Plant Grow Lights and regular lamps Firstly, Plant Grow Lights have significant spectral differences. Unlike ordinary lamps, Plant Grow Lightss use specially designed light sources that can emit blue and red spectra that meet the needs of photosynthesis and plant growth, optimizing plant photosynthesis and the demand for specific plant growth cycles. Research has shown that blue light can enhance plant photosynthesis, while red light is beneficial for stimulating plant growth, prolonging plant growth period, and enhancing plant photosynthetic capacity. Therefore, Plant Grow Lightss can better support plant growth, improve yield and quality in environments such as culture rooms, greenhouses, and flower planting. Able to control lighting time and intensity Secondly, Plant Grow Lights can control the duration and intensity of light. During plant growth, light duration and intensity are crucial factors. Plant growth lights can control subtle light adjustments and can be regularly turned on and off, maintaining a certain light cycle and lighting intensity to better support plant growth and development, providing plants with lighting conditions similar to natural sunlight. Plant Grow Lightss have significant advantages in indoor or poorly lit environments, as they can support the growth and yield improvement of specific plants. Therefore, in future plant planting production and environmental protection, Plant Grow Lightss will undoubtedly play an important role.

From May 1st to May 3rd, 2022, there will be a holiday for a total of 3 days. Work on May 4 (Thursday) and May 8 (Saturday).

The application of ultraviolet technology in the field of disinfection has gradually become popular. With its advantages of high efficiency and reliability, ultraviolet disinfection lamps are widely used in fields such as homes, healthcare, food, cosmetics, and water treatment. However, the efficacy of ultraviolet lamps is not determined by the duration of use, but rather by calculations and arrangements based on different fields. Medical industry The medical industry is one of the important application fields for ultraviolet lamp disinfection. Medical equipment, operating rooms, air, surfaces, etc. all require ultraviolet disinfection. The disinfection time varies depending on the size and classification of the equipment. Usually, using 254nm ultraviolet disinfection lamps for relatively small medical devices takes only 10-20 minutes to complete, while large equipment and operating rooms require the use of multiple tubes or lamps in combination. Depending on the size, layout, and supplementary air circulation conditions of different equipment, it generally takes 30 minutes to 2 hours. Food industry In the food processing industry, the requirements for environmental hygiene are very high, and the disinfection requirements for bacteria and viruses are also very strict. The disinfection of ultraviolet lamps in food processing environments requires attention to different types of food and the level of cleanliness. In general, the UV Lights on the surface of the food processing area needs to be used for at least 30 minutes, and the UV Lights on the ceiling needs to be used for 60 minutes, with an ambient temperature not exceeding 50 ° C. In summary, the disinfection time of ultraviolet lamps varies in different fields and needs to be determined based on specific circumstances. The disinfection time is not as long as possible, but should be calculated comprehensively based on multiple factors such as equipment size, power, number of light tubes, program used, environment, and working state. When using ultraviolet lamps for disinfection, it is also necessary to pay attention to safety measures, safety distance and time, to prevent damage to the human body or equipment.

Queendom LED Lighting Product Series: Solar Lighting, Commercial Lighting, Industrial Lighting, Outdoor Lighting, Traffic Lighting

Focus on LED characteristic lamps: industrial lighting, agricultural lighting, intelligent lighting series for cold chain industry, PCBA/LED lamps OEM/ODM, etc.;

More: https://www.queendomlamp.com/lights-lighting/

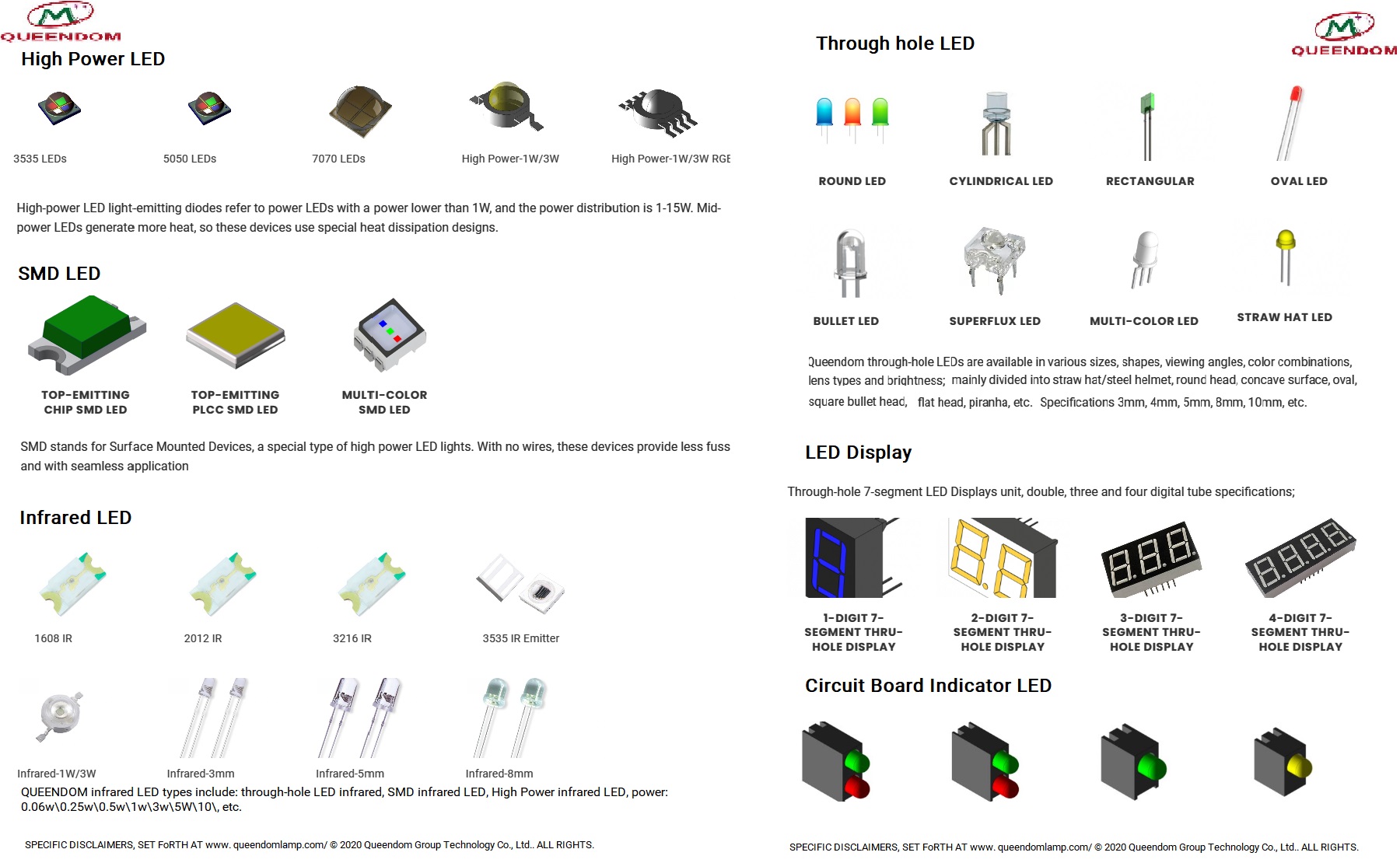

High-power LED, DIP LED, through-hole LED, SMD LED, infrared emitter LED, photodiode LED, LED display, circuit board indicator LED receiving module and component series products

For details, please refer to: https://www.queendomlamp.com/leds-lamp/

Optical lens is the core component of modern optical instrument, and also one of the most basic constraints of optical instrument. It can control the transmission, distribution and focus of light, so as to adjust the optical path, optical quality and optical distribution of transmission light, so that optical instrument can achieve imaging, amplification, adjustment, analysis and control functions. The main function of optical lenses Focusing light; An optical lens can focus light and convert scattered light into concentrated light. This enables optical instrument to image, amplify and control light. Adjust the optical focus position; An optical lens can change the focal position of an image, enabling it to be imaged at a further or closer distance. This makes the optical system more flexible and able to adapt to imaging needs in different scenarios. Improve imaging quality. Optical lenses can improve the clarity, dispersion, and astigmatism of optics and imaging. By changing the shape and size of the lens, the dissipation and dispersion of light are suppressed, making the image clearer and more realistic. Adjust the size and angle of the field of view. An optical lens can adjust the size and angle of the field of view, changing the range and angle of the imaging field of view. This makes optical instrument more versatile and can be easily observed and measured in various environments. Improve the accuracy and stability of optical instrument. Optical lenses can bring higher measurement accuracy and stability to optical instrument, enabling them to work in more stringent environments, such as high temperature, low temperature, high humidity, low pressure, etc. In a word, optical lens plays a crucial role in modern optical instrument. It can control the transmission, distribution, focusing and control of light and achieve various optical functions.

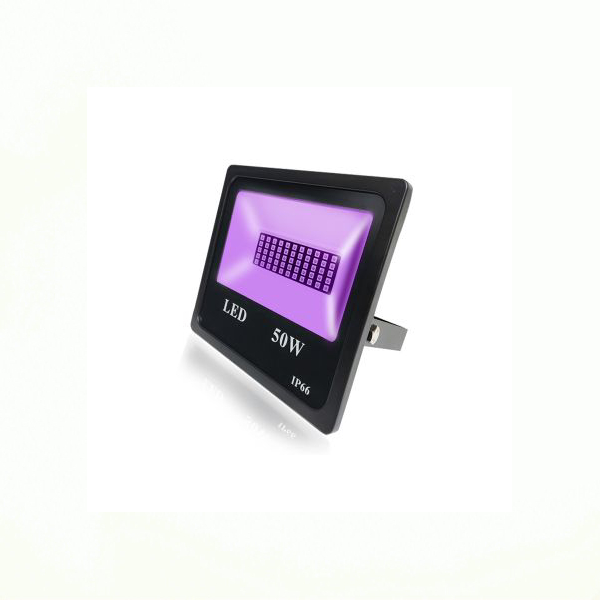

uv flood light is a uv led flood light lighting device . uv light for plants color is deep purple or purple red, Scenarios Applied for indoor and outdoor use,

Optical instruments are an important optical component that plays an extremely crucial role in modern optical research. optical instruments are widely used in fields such as laser, fiber optic communication, medical, aerospace, and have important application value. This article will introduce the definition, types, and application fields of optical instruments.

Round LEDs and energy-saving lights are both popular lighting devices in the modern lighting field. They have many similarities, both of which are aimed at energy conservation and environmental protection, improving energy utilization efficiency. However, there is still a gap between the two, so which is better and more energy-efficient, Round LEDs or energy-saving lights? Let’s analyze and compare below.

LED display is a high brightness display screen based on LED technology, which is suitable for various indoor and outdoor occasions and has wide applications in information dissemination, advertising dissemination, entertainment display, and other aspects. The following will introduce the functions and characteristics of LED displays.

Photodiode LEDs, also known as Photodiode LEDs, are electronic components that can convert light into electrical energy. Its structure is similar to a regular PN junction diode, but there is a transparent window above the PN junction for receiving optical signals. Photodiode LEDs are widely used in fields such as communication, optoelectronic detection, automatic control, and medical equipment.

Infrared LEDs play a significant role in many fields, using semiconductor technology to convert electrical energy into infrared light energy, with various applications. Below, we will talk about their roles in various fields.

Through hole LEDs is a type of light bead installed through holes on a circuit board, which can be used in various applications such as indicator lights and lighting. Compared to surface mounted SMD light-emitting diodes, it has higher stability and durability.

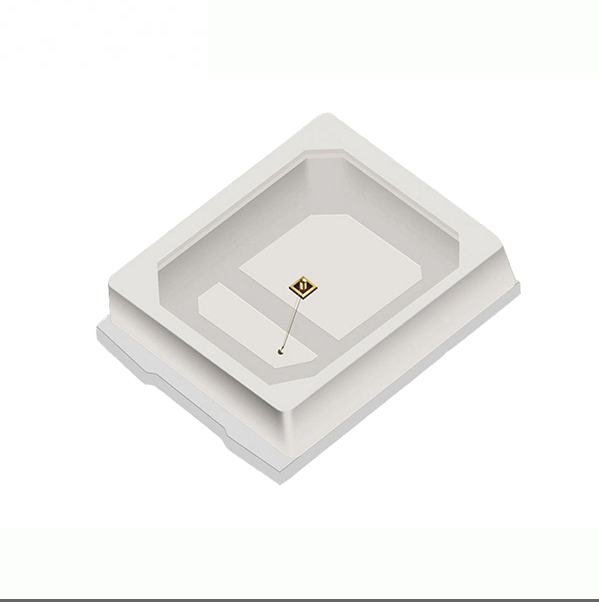

SMD LED is a surface mounted lamp bead suitable for various electronic circuit applications such as indicator lights, lighting, and displays. In daily use, its wavelength, brightness, appearance, and other parameters have certain classifications.

UV LED is a device that uses UV radiation for sterilization and disinfection. After a certain period of exposure, it can kill bacteria and viruses, and has a good disinfection effect. So what is its disinfection effect? What should I pay attention to when using? Let’s take a look together. The disinfection principle of UV LEDs Firstly, the disinfection principle of UV LEDs is based on the bactericidal effect of UV radiation. UV radiation is a high-energy electromagnetic wave with short wavelengths and strong penetration, which can damage the DNA structure of bacteria and viruses, making them unable to replicate and grow, achieving the effect of sterilization and disinfection. Pay attention to these when using UV LEDs Secondly, there are several points to pay attention to when using UV LEDs. Before use, the surface of the lamp should be cleaned and free from dust and dirt; When using, glasses should be worn to avoid direct exposure of the eyes to UV radiation; Before use, all indoor light sources should be turned off and the indoor color should be kept dark; The irradiation time needs to be determined based on the object and environment, generally ranging from 15 to 30 minutes or even longer; Do not let pets enter during the irradiation process to avoid adverse effects. In addition, UV LEDs are also divided into three wavelengths: UVA, UVB, and UVC. Among them, UV LEDs with UVC wavelength can kill most viruses and bacteria and are the most commonly used disinfection tool. However, it should be noted that UVC UV LEDs can cause damage to the skin and eyes if the exposure time is too long or the exposure distance is not appropriate. In summary, UV LEDs have excellent disinfection effects. When using them, it is necessary to pay attention to disinfecting objects, irradiation time, and not excessively exposing skin to UV LEDs. At the same time, when choosing and purchasing UV LEDs, products with good quality and high safety should be chosen.

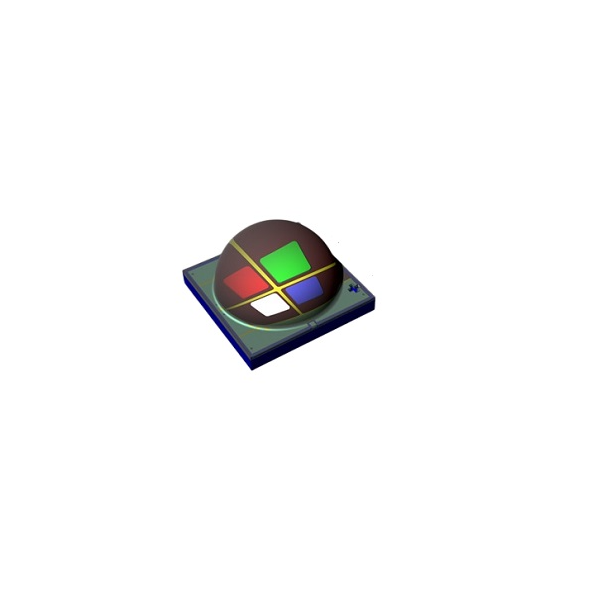

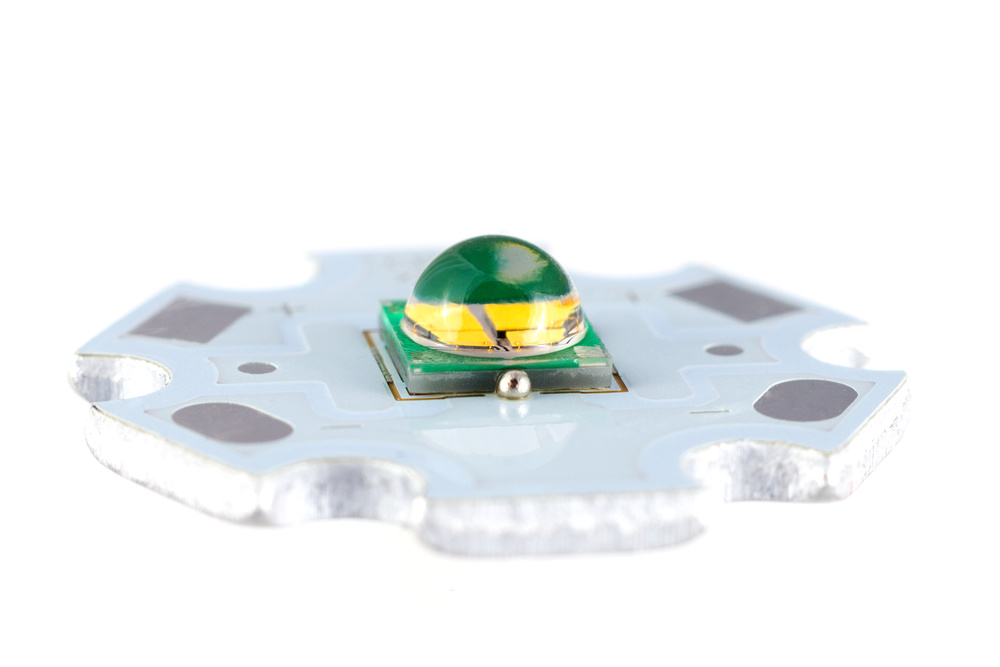

With people’s pursuit of green environmental protection and efficient energy conservation, high power LEDs has become a development trend in the lighting industry. What are the characteristics and principles of high power LEDs? Let’s take a look together. Compared to ordinary LED lamps, high power LEDs A high power LED is a semiconductor device that has higher power and light output compared to ordinary LEDs, typically above 1 watt. This also makes it widely used in fields such as lighting, car lights, and signal lights. The working principle of high power LEDs The working principle of high power LEDs are similar to that of ordinary LEDs. When a voltage is applied forward through its two electrodes, a p-n junction is formed in the area where they come into contact. In the p-n junction, electrons and holes recombine, releasing energy and producing photons. The energy and wavelength of such photons depend on the properties of the semiconductor material. The semiconductor materials used in high power LEDs are usually III-V semiconductor materials with a wide bandgap of gallium phosphide and a direct transition to the bandgap. So, what are the differences between high power LEDs and ordinary LEDs? There are two main differences here. Firstly, high power LEDs can withstand higher currents and power, thus generating stronger optical output. Secondly, high-power LEDs typically use multiple light-emitting chips and lenses to achieve higher light output and a wider illumination range. This design can also effectively reduce light attenuation and improve service life. So high power LEDs have the advantages of high efficiency, energy conservation, long lifespan, and environmental protection, and play a significant role in the lighting and electronics industries in daily life.

PCR Optics LED Lens Tube is an optical component used in PCR fluorescence analyzers, medical PCR Optics systems, etc. Queendom launches pcr optics led

Package size of 7070 SMD high-power ceramic LED: 7mm*7mm*1.0mm, 3.0-12V, current 350mA-1500MA. The special heat dissipation design makes the heat of the chip be exported instantly, effectively prolonging the service life of the product. The heat conduction speed of this product is 10 times that of imitation lumen.

Also known as a curing lamp or an ultraviolet lamp, and a lamp that emits ultraviolet rays is called a UV curing lamp because ultraviolet rays (ultraviolet rays) have a curing effect. The curing here refers to UV curing of UV resin, and ultraviolet rays can cure UV resin (ink, UV coating, UV glue, UV varnish, etc.).